Welcome to: Ningbo Ligong Online Monitoring Technology Co., Ltd

! Hotline:400-8269-696

Current location:Home> Products&solutions > Transformer intelligent cooling monitoring system

Products

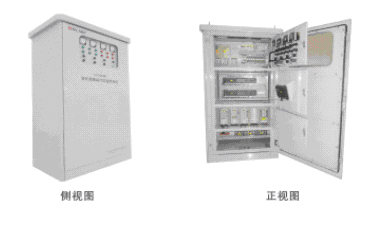

Intelligent cooling monitoring system of CCS2000 transformer

● a master with a dual PLC combined with the man-machine interface to achieve intelligent monitoring and control of the cooling system;

● high and low temperature control, moisture, lightning protection, anti-jamming measures to ensure stable and reliable operation of the system;

● Transformer cooler with "manual" ralph lauren pas cher, "automatic" and "remote" rdquo; three control methods for users to choose;

● system real-time acquisition of transformer oil temperature, load current, winding temperature contact signal and analog signal, and according to these signals by a certain logic

To achieve the cooler automatic start and stop control, reduce maintenance;

● Real-time monitoring of system status, timely detection of potential failures, failure to automatically recover after recovery to meet the substation unattended requirements;

● configuration of dual PLC fault emergency circuit to improve operational reliability and security;

● perfect cooler start delay control;

● equipped with emergency operation box, to ensure that the control power to disappear when the cooler can work;

● IED can be configured for cooling units based on the IEC61850 communication protocol.