Thunderbird Power Dispatching Production Management System (DMIS / OMS)

OMS Thunderbird power dispatching production management system is built on a unified operating platform. The running platform includes hardware and network platform, software running platform and application system support platform. On the basis of unified operation platform, the system adopts N layer B / S System architecture, the right to control the system security mechanism to component mode for the development model, to provide users with a complete thin client to achieve system security control easy to expand the network version of distributed computer information management system.

system introduction:

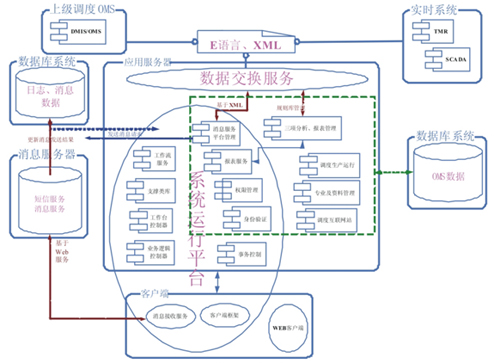

OMS hardware and network platform is in the power secondary system security protection rules, the establishment of high security requirements to ensure that the power network architecture, power dispatch operation management system to achieve the network foundation. Software running platform is based on user needs and the actual situation to establish suitable for OMS system to run the software environment, including the operating system and database, the system software operating platform are purchased by the manufacturer authorized good performance of large commercial software to ensure the stability of the software operating platform , Safety and reliability. Application system support platform is Thunderbird company based on years of development experience in self-developed business system support platform, through the object modeling tools, workflow management tools, reporting services tools, application production and publishing tools, messaging services, rights management Integrated platform, fast and convenient and stable realization of the construction of business systems, and for the user to achieve a convenient change in demand for business since the expansion of the function to ensure that the system standardization, security and scalability; the same time the platform for users to provide data exchange services or standards Interface data management, SCADA / EMS, TMR (ELS), vertical or horizontal OMS and other data exchange, and to achieve the seamless system within the system, to achieve the existing system production MIS, equipment accounting, file management, SCADA / EMS, TMR (ELS) Will be the construction of the system's interconnection interface, a wider range of resource sharing.

Business function design and implementation of advanced management ideas as a guide, combined with ERP, BPR / BPM and other management concepts, in line with the scheduling business management, with the role of optimization of the information system, from data collection, business process, data analysis And to provide managers with several levels of decision-making to achieve the business functions of the system, the system through the workflow management tools and data exchange services to achieve vertical and horizontal two-way business management. Through the statistical analysis of information and advanced production management system approach to improve the scheduling of production decision-making level and efficiency, reduce labor intensity.

The system construction fully integrates the management functions and data processing functions needed to schedule the production management, and realizes the deep integration of the entities (organization, personnel, equipment) and the contact (between each other), with the entity as the center, Expansion of value-added services; fully embodies the field of scheduling information and business management and data processing and \ "the system features, but also to fully meet the actual needs of scheduling production management.